The plastics waste pollution is worsening in Nairobi, Kenya with commercial wastes ending up in landfills with no practical use. That is until a young materials engineer there thought of a solution to use these discarded plastics and turn them into bricks – those that are even stronger than concrete.

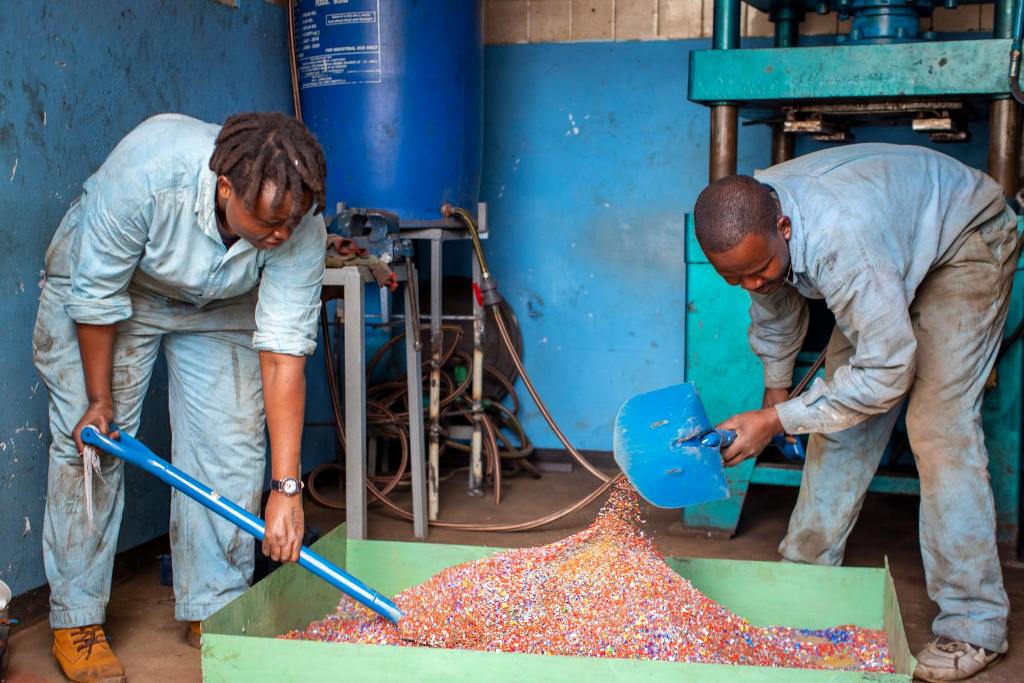

Through her company called Gjenge Makers, Nzambi Matee is revolutionizing the way bricks are made in Nairobi. She is using commercial plastic wastes and sand to create brick with residential and commercial applications using machines she personally designed.

The process of forming the construction material involves compressing and heating the plastics, later combined with sand to reach its final form.

Her company uses a variety of plastics commonly found in the household including high density polyethylene, low density polyethylene, and polypropylene. Notably, Matee does not use PET or polyethylene terephthalate, which is commonly used for plastic bottles.

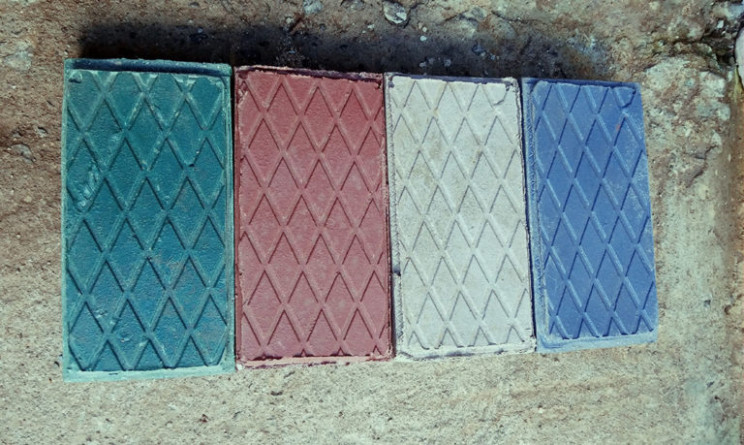

Regardless, thanks to the fibrous structure of plastics, the resulting brick is lightweight and less brittle than concrete.

Matee said in an interview with Reuters, “Our product is almost five to seven times stronger than concrete,” referring to their current line of pavers and bricks.

Reports say that the Gjenge Makers factory has the capacity to produce up to 1,500 bricks per day. The sources of the plastics are either donations from local packaging factories or purchased plastic bundles from recycling companies.

To date, since the company’s inception in 2017, the factory has recycled 20 tons of plastic. Currently, their standard grey bricks are sold at about $7.70 per square meter, versus the $98 per square yard rate for concrete produced in the United States. Other bricks are available depending on thickness and color.

Sources: EcoWatch | Reuters

Photos via Gjenge Makers and Reuters